Our in-house CNC machine shop allows us to push for greater precision, obtain design input from the machinist making the parts, and make as much in-house as possible for greater quality. We get to work with brilliant people who are specialists in the CNC world, which allows us to be self-sufficient. Our team is scrappy, likes to make new things, and never turns down a challenge. Our team machines what others say shouldn't be a machined part and consistently push past their comfort zone.

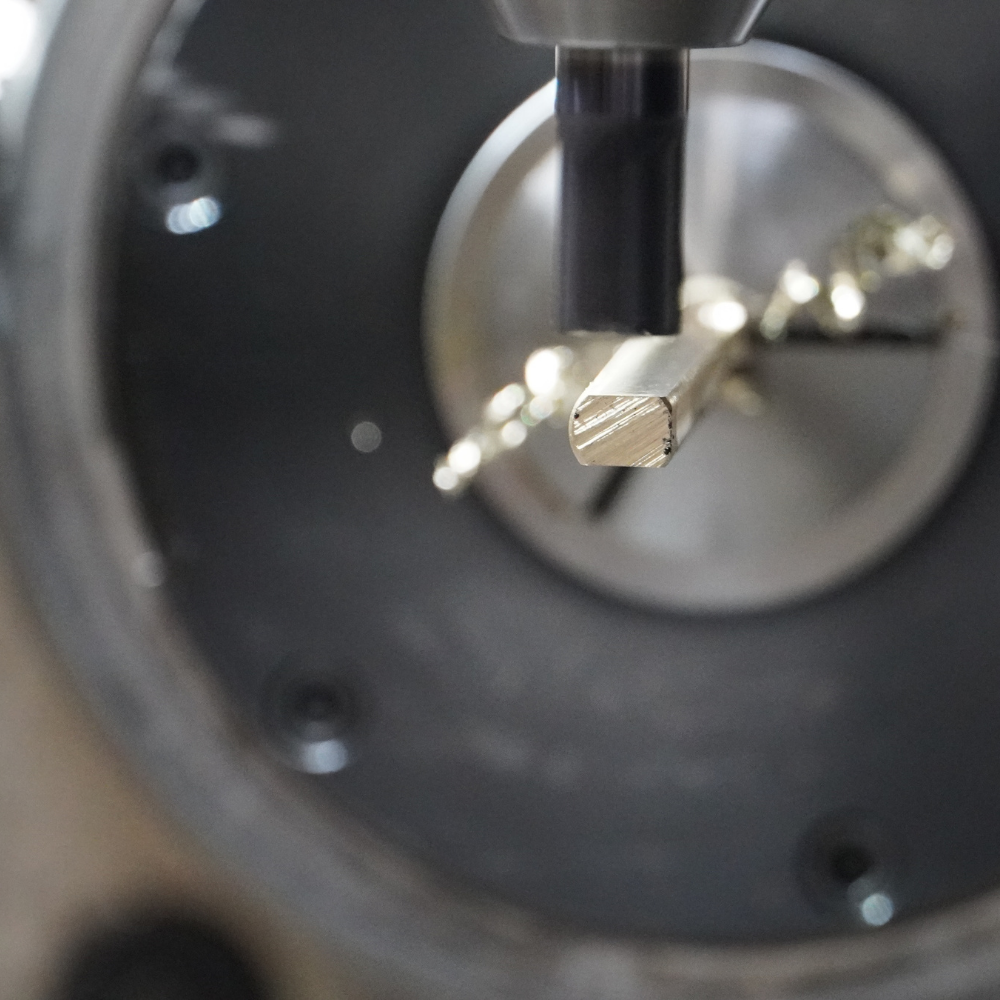

CNC Mill and Lathes

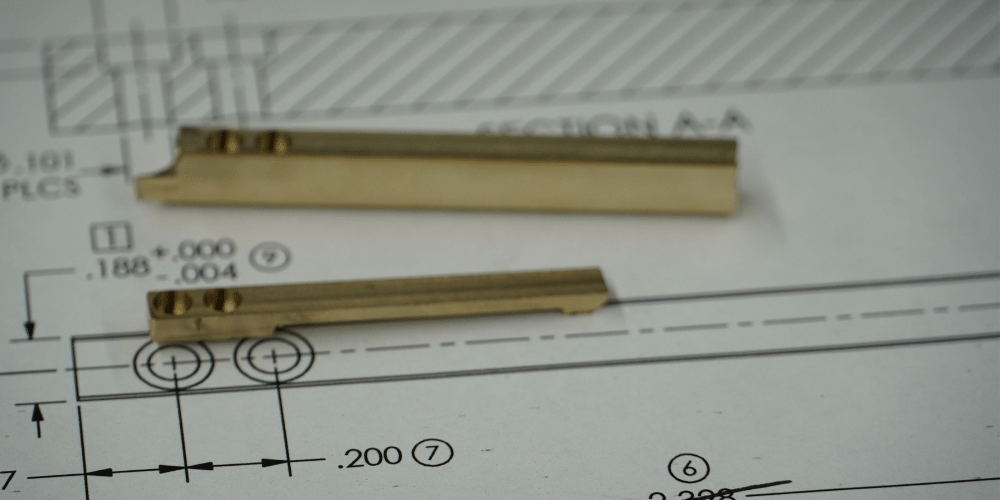

Our sister company has been machining parts for over 30-years and has a large, diverse availability of machines. Our team can produce complex components that complement each other by having access to both lathes and mills. CNC Swiss Lathes machine our pen bodies and can run 24/7. CNC mills machine complex parts. Our pen clips are some of the only non-stamped clips on the market.

Machine Operator Design Input

All our products are collaboratively designed with every person who has a roll in making or selling the product. By having the machinist guide on design features that match their machine capabilities, we can produce the highest quality goods that will stand the test of time.

Simplification to produce EPA-regulated antimicrobial products

Being self-sufficient greatly benefits us, as the antimicrobial* copper we machine to make products is regulated by the EPA. Any supplier who touches the copper must be registered with the EPA and has to comply with the required reporting and track ability. The more third-party companies we partner with, the more barriers to market here are, i.e., cost & time.

Headquartered in Fort Worth, TX, our sister company Horizon Tech Industries has been manufacturing custom parts for over 30-years. Our small team is very knowledgable within their specialized niches and has the passion never to stop learning. We take a collaborative approach to projects and engage every person who has a role in the project. From CNC machining, metal stamping, and additive manufacturing, our team can tackle any project.